Process

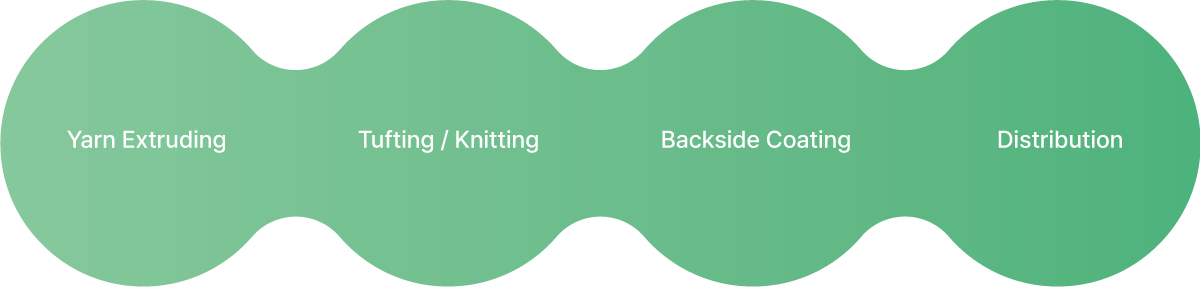

With continuous technological development and innovation, GSTG produces and distributes over 30 types of artificial turf and related products through its One-Stop Total Solution System.

From yarn production to weaving · processing · and distribution GSTG’s One-Step Total Solution System provides an all-in-one service.

Yarn Extruding

Yarn Production

Depending on the purpose of the artificial turf, we mix Polypropylene (PP), Polyethylene (PE), and Nylon with masterbatch and UV protection agents to produce high-durability artificial turf yarn that withstands heat and UV exposure.

We have the capacity to produce:

PE (Polyethylene) yarn: 8T/dayPP (Polypropylene) & Nylon Texturing (Crimping) yarn: 4T/dayTotal production capacity: 12T/day (360T/month)Our production supports sports turf, landscaping turf, and hybrid turf applications.

Tufting / Knitting

Weaving Process

GSTG utilizes both Tufting and Knitting (Raschel) weaving processes.Tufting Method: The standard artificial turf weaving process, used for landscaping and sports turf.Knitting (Raschel) Method: A seamless, highly durable weaving technique applied to hybrid turf and sports turf such as golf mats.

Our facilities include:Tufting Machines: 3/8 Gauge – 2 Lines, High-speed 5/32 Gauge – 2 LinesKnitting Machines: m-wide Knitting Machines – 4 Lines, 2m-wide Knitting Machines – 6 Lines, Total: 10 Lines for golf courses, landscaping Raschel turf, and soccer field hybrid turf production.

Backside Coating

Processing

We enhance pull strength and durability by applying heat treatment or SBR coating to the back of the woven artificial turf.

Our final processing facilities include:75m-long (24m Chamber) coating lineProduction capacity: 23,000㎡/day, 700,000㎡/monthWe offer customized coatings for artificial turf backing, carpet backing, and other consumer needs.

Distribution

Installation & Construction

Our in-house installation team, equipped with professional construction equipment, ensures high-quality installation of artificial turf for landscaping, general use, and sports applications.

We provide a fully integrated system from yarn production to installation, with specialized equipment such as:Roll Open MachineDrop-type Sand SpreaderUni RakeBrushing & Compression RollerAdditionally, we maintain a full range of hybrid turf installation and A/S (after-service) equipment, ensuring flawless field harvesting, on-site installation, and maintenance systems.